The Torque Monitoring Revolution...

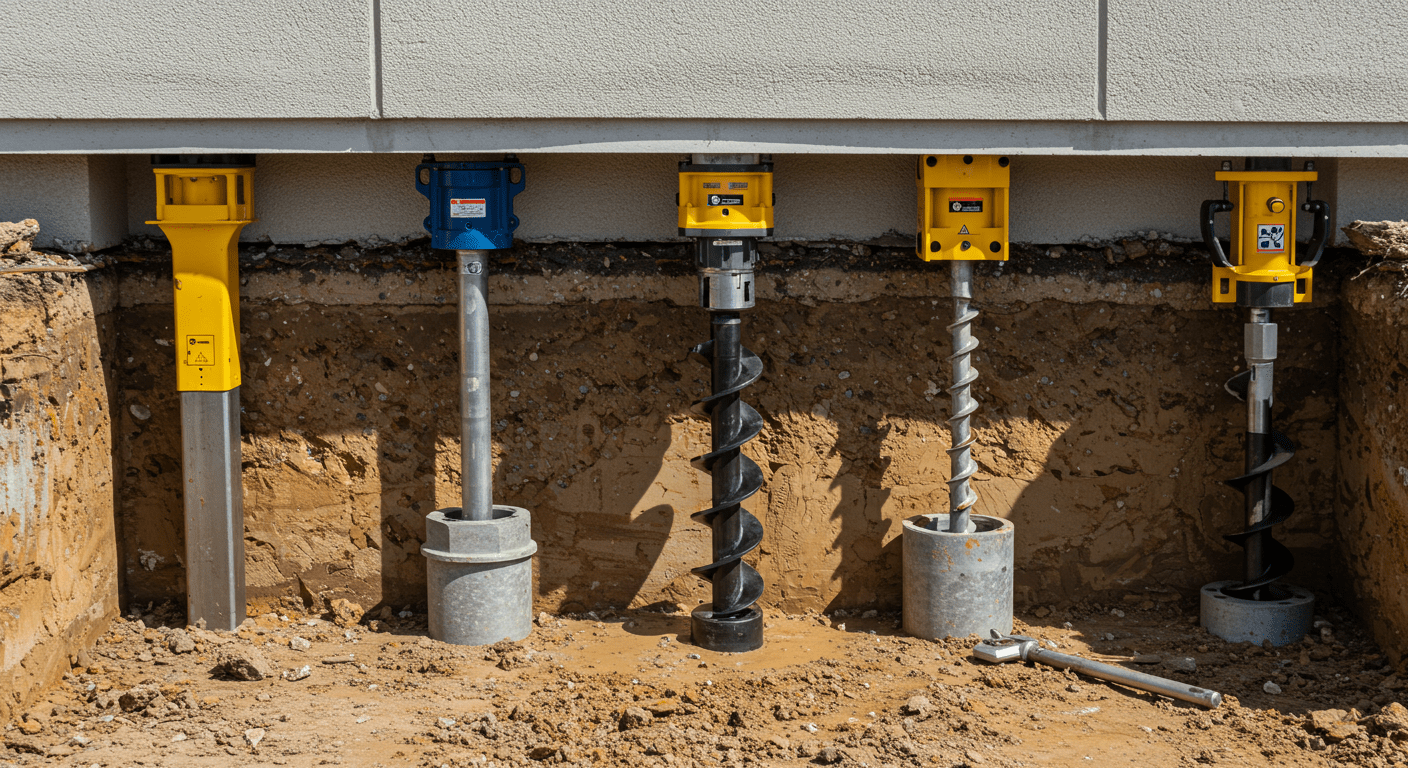

Digital torque monitors have revolutionized the way helical piers are installed, offering a level of precision, efficiency, and reliability that was once hard to imagine. Here are the significant ways in which digital torque monitors have reshaped the landscape of helical pier installation.

Real-Time Torque Measurement:

Data-Driven Decision-Making

Early Detection of Installation Issues

Optimized Pier Sizing and Configuration

Quality Assurance and Documentation

Efficiency and Time Savings

Conclusion

The integration of digital torque monitoring technology into helical pier installation has redefined the standards of precision and efficiency in foundation engineering. These monitors empower engineers and installers with real-time data, allowing them to optimize the installation process, ensure quality, and adapt to varied soil conditions. As the construction industry continues to embrace technological advancements, digital torque monitors stand out as a revolutionary tool that has truly changed the way helical piers are installed, setting new benchmarks for accuracy and reliability in foundation construction.

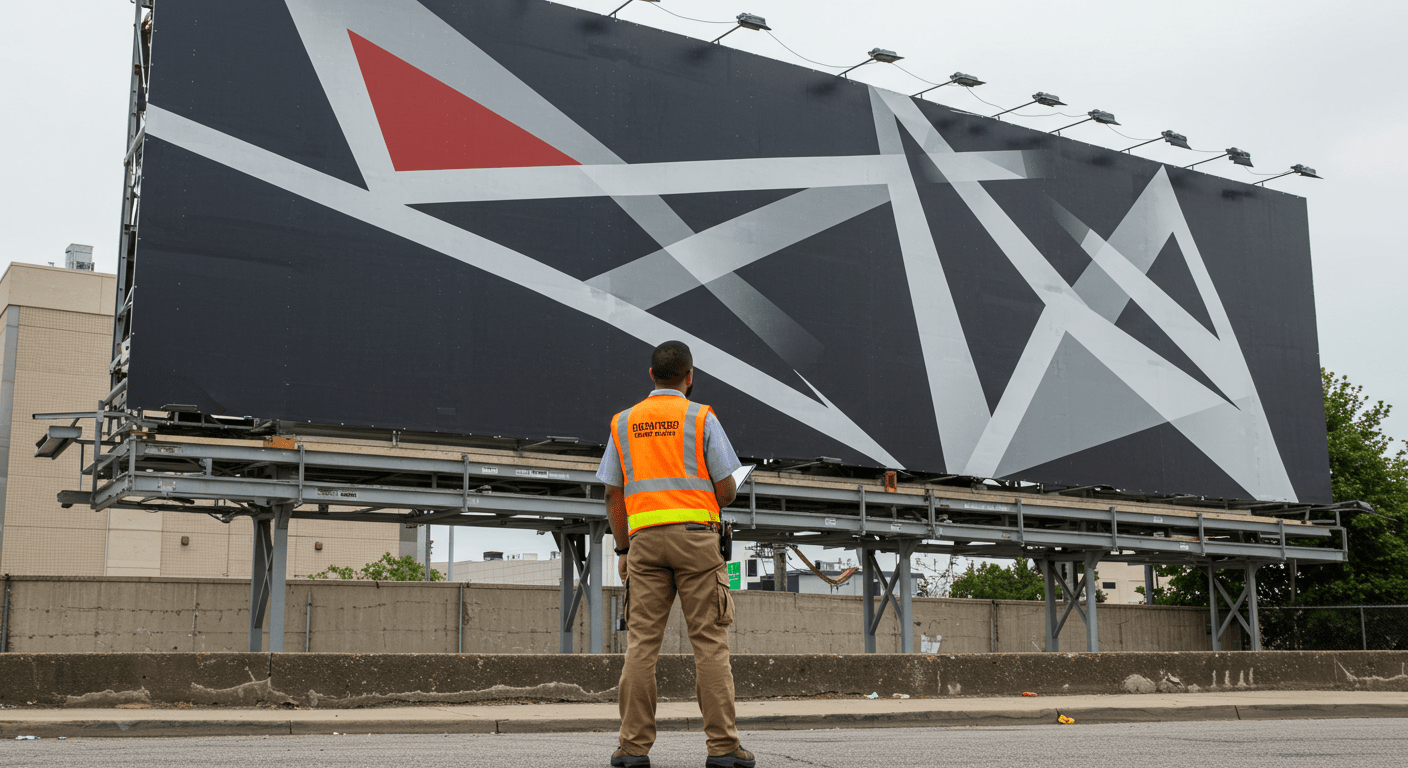

PIER EXCEL offers digital torque monitoring on most helical pier installations. The quality assurance and insight that comes from digital torque reporting makes engineers content and clients happy.